- Home

- Products

- TrueSpeed Sensor

- Feltest TrueSpeed Sensor (for SpeedController)

Feltest TrueSpeed Sensor (for SpeedController)

MEASURE WHAT MATTERS: SURFACE SPEED

The TrueSpeed Sensor is the fastest way to check the actual surface speed of your rolls and machine clothing – helping you easily identify speed differences caused by input errors and slipping drive rolls.

Why relying on the Drive Control System is a bad idea

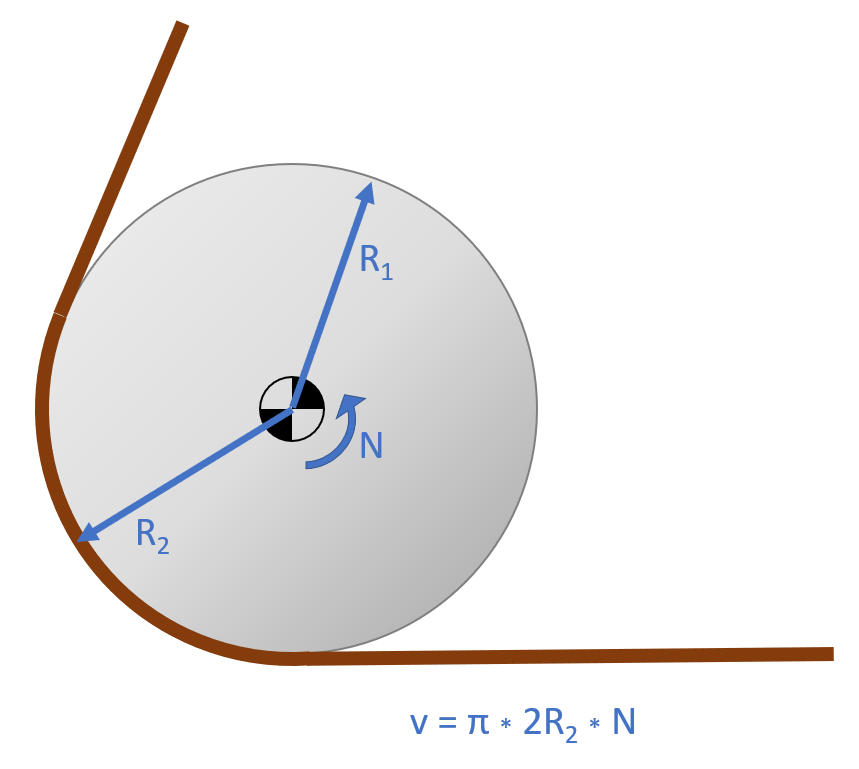

Every piece of Paper Machine Clothing must run at precisely controlled speeds. But controlling those individual speeds comes from the drive control system making a calculated guess: multiplying the roll diameter and the thickness of the felt or fabric with π and the revs of the drive: v(fabric) = π * 2 * R2 * N

Manually inputting data puts you at risk of all sorts of errors, from typos and incorrect data to forgetting to update the data after changing the fabric. Combine this with the fact slipping drive rolls often go undetected—while the drive control system shows all section speeds are correct—and you’re left facing numerous breaks, unusual draws, sheet surface defects, or worn-out machine clothing.

Measure within a minute: no more guesswork

The TrueSpeed Sensor is the fastest way to check the actual surface speed of your rolls and machine clothing—helping you easily identify speed differences caused by input errors and slipping drive rolls.

The sensor is ready for use in just a few seconds, and the measurement itself will take about the same.

The TrueSpeed can be used on almost any position, whether wet or dry, hot or cold, stable or vibrating.

Fill in the form and download the brochure

Tachometers are standard equipment, but none are as suitable for use on a running paper machine as the Feltest TrueSpeed Sensor. It is a robust construction and all parts are secured. The big diameter measuring wheels can handle speeds up to 3000 m/min and the pivoting handgrip assures auto-aligned of the device in the machine running direction.

FAQ's

Measure the true speed within a minute. Here are some frequently asked questions about the TrueSpeed Sensor:

Hold the measuring wheel above and in-line with the running direction of the roll or fabric. Assure that the pivot point between wheel and handle is not at its limits, but can move freely.

Move the measuring wheel down until it is in good contact with the roll or fabric; apply limited pressure to prevent slip but without distorting the rubber tire or the fabric or felt.

For a step-by-step guide on how to connect the TrueSpeed to the SpeedController, please take a look at our TrueSpeed Sensor User Manual.

The TrueSpeed Sensor has been designed specifically for the Paper Industry. The aluminum construction, the large wheel with high quality metal bearings, and the slip-reducing pivot can easily handle speeds of over 2300 m/min | 7500 fpm and give accurate and reliable results.

The small wheels of standard tachometers create an incredible number of revs, quickly overloading and disengaging of the plastic parts. The lack of a self-alignment system on standard tachometers leads to inaccurate measurements and the unwanted loss of the (click-on) measuring wheels.

The machine’s DCS is a calculated guess of the surface speed of every driven roll: multiplying the roll diameter plus the thickness of the felt or fabric with π and the revs of the drive. The guess is in the fact that the exact thickness of the felt or fabric is not known and the assumption that the calculation uses the correct roll diameter

The TrueSpeed measures where it matters: on the surfaces that touches the sheet. Deviations caused by incorrect roll diameters or thicker/thinner felts than anticipated, are all taken out of the equation with a TrueSpeed measurement.

The TrueSpeed Sensor is ready to use in just a few seconds, and the measurement itself will take about the same.

The standard wheel with a rubber tire is used in the following situations:

• On paper machine rolls (incl. dryer cans) with any type of roll cover;

• On wet or dry forming fabrics and dryer fabrics;

• On wet or dry press felts if the felt is sufficiently supported (for example when measuring on the stretch roll or on an Uhle box);

The special wheel with the “only for wet felt” inscription is to be used on wet press felts, on locations where the felt is not directly supported, so at spots between two felt rolls. As the surface of this wheel is quite rough, it is advised to use this wheel only outside the paper sheet’s run.

“We discovered a difference during couching that we didn't have a correct picture of until now. Now we can convert this into an action. Also applicable for several areas, we benefit from it.”

— BERT N. (THE NETHERLANDS)

“Identify unwanted speed differences due to input errors and slipping drive rolls”

— MARCEL LENSVELT

“Identify unwanted speed differences due to input errors and slipping drive rolls.”

— MARCEL LENSVELT

| Specifications | TrueSpeed Sensor |

|---|---|

| Required control unit | Feltest SpeedController |

| Measuring principle | Counting pulses from magnets in the wheel |

| Range | 10 - 3000m/min | 30 - 9800 fpm |

| Accuracy | ±0.05% of full scale |

| Read-out units | m/s, m/min, km/h, fps, fpm, fph |

| Max. length including handgrip | 300 mm | 1 ft |

| Length of cable | Approx. 2 m | 6.5 ft |

| Total weight | 1.2 kg | 2.6 lbs. |

Get your TrueSpeed Sensor Quote

Get your quote instantly by adding it to your shopping basket and pressing the Request Quote button, or buy directly in our ONLINE STORE.

Any questions? Just reach out and our sales team will contact you shortly.