Caliper Profiler

The Feltest Caliper Profiler measures the caliper, or thickness of forming fabrics and press felts on the fly.

Caliper values help to estimate the remaining life of forming fabrics. For poorly dewatering press felts, the caliper helps to differentiate compaction, contamination and wear.

Version

Monitoring of press felts

With every nip pass, a felt’s ability to recover from the nip impact decreases. Depending on felt design and press load, the felt becomes increasingly compacted. Establish a typical compaction curve for every felt position; this is your reference. Compare the compaction curve of any (trial) felt with this reference and you know precisely what is going on.

A thin felt doesn’t necessarily mean it is compacted; it can be worn too. To properly assess the condition of press felts it is best to combine the caliper test results with information on the felt’s openness as measured with the Feltest Airspeed Sensor and Feltest RealVac.

Monitoring forming fabrics

Due to the profile function you will always detect the minimum caliper within 30 cm/1 ft from the edges. This measured caliper can then be related directly to the minimum caliper as stated by the fabric supplier.

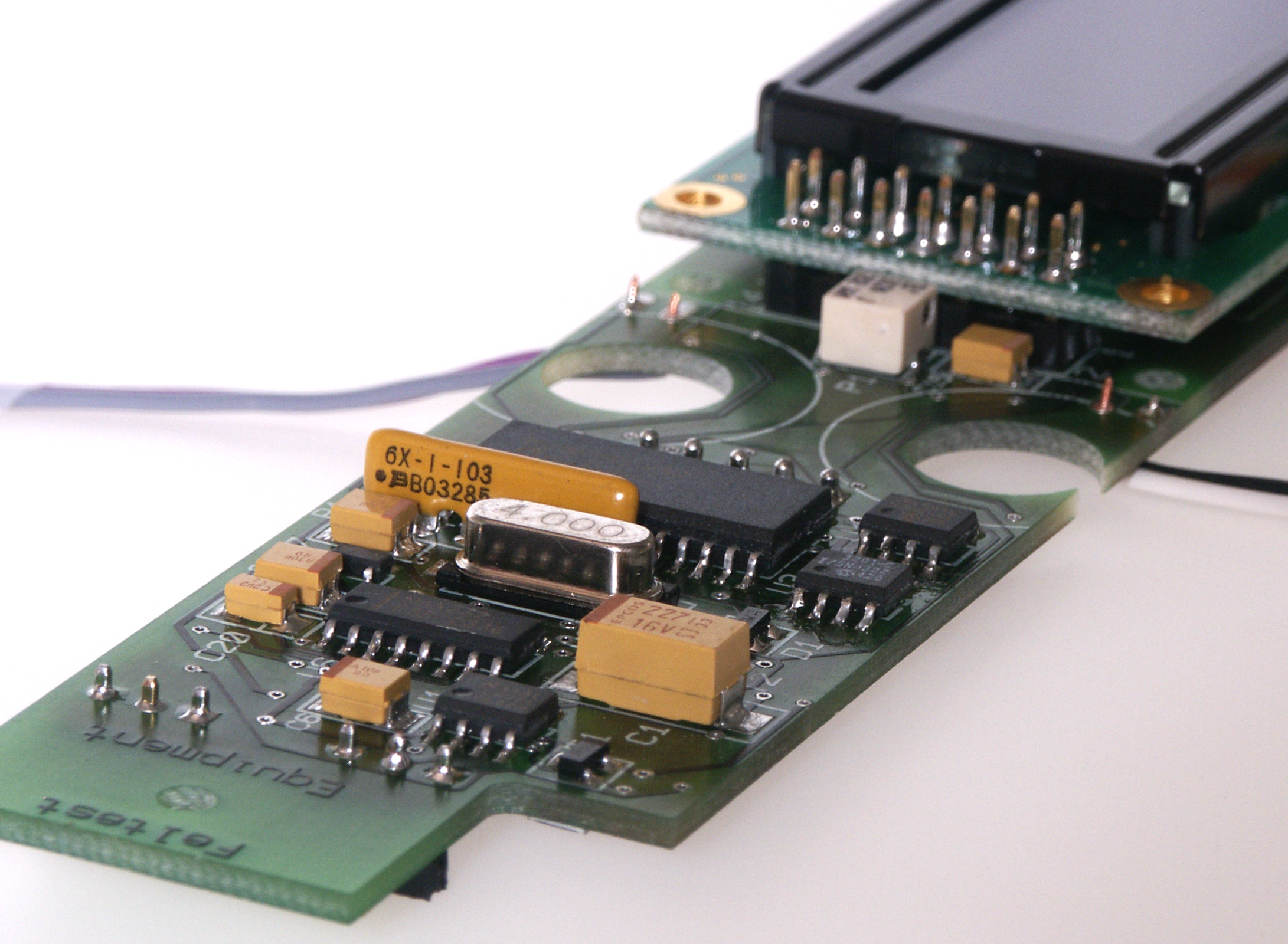

Ergonomic design

The ergonomic and rigid design is equally suitable for both left and right-handed people. The red trigger has two functions: pulling the trigger opens the mouth of the instrument and pushing the trigger starts recording the measured values into memory. After the measurement, you can read the results safely outside the fabric’s run.

The Feltest Caliper Profiler has been designed for use in the corrosive environment of paper mills. It withstands spray water, dust, and mechanical shocks and is practically maintenance-free. The Caliper Profiler is shipped in a custom carrying case; the delivery includes a manual with calculation examples, a USB cable, and software to download the data to your PC.

Fill in the form and download the brochure

The Caliper Profiler measures the true fabric caliper, not influenced by a water film or small contaminations on the fabric’s surface. The unique shape of the feelers is designed for the best performance on running forming fabrics and press felts. The high spring load gives an excellent reproducibility and makes the results highly independent from the person performing the measurement.

FAQ's

A paper machine runs 24/7 so if you must make decisions for the next shutdown, you need to collect data on the fly. Luckily, there's the Caliper Profiler.

It can be used on running forming fabrics, press felts and dryer screens, provided they don’t have a metallic clipper seam.

“Accuracy, reproducibility and reliability in a paper mill environment, these were the design objectives. A highly dedicated instrument for any professional dealing with paper machine clothing.”

— MARCEL LENSVELT

“Accuracy, reproducibility and reliability in a paper mill environment, these were the design objectives. A highly dedicated instrument for any professional dealing with paper machine clothing.”

— MARCEL LENSVELT

“Accuracy, reproducibility and reliability in a paper mill environment, these were the design objectives. A highly dedicated instrument for any professional dealing with paper machine clothing.”

— MARCEL LENSVELT

| Specifications | Caliper Profiler |

|---|---|

| Accuracy and units | ± 0.01 mm | ± 0.40 mil |

| Dimensions (l x h x d) | 431 x 127 x 25 mm | 17.0 x 5.0 x 1.0" |

| Weight (including carrying case) | 1.8 (4.8) kg | 4.0 (106) lbs. |

| Battery | Standard disposable 9V battery |

| Typical battery life | > 1 year |

| Protection | IP64 |

| PC connection | USB - cable included |

Get your Caliper Profiler Quote

Get your quote instantly by adding it to your shopping basket and pressing the Request Quote button, or buy directly in our ONLINE STORE.

Any questions? Just reach out and our sales team will contact you shortly.