Your fabric tension is too high - without you knowing it

Discover the cause and effect of measuring low tension values.

Discover the cause and effect of measuring low tension values.

Most paper mills use a mechanical tension gauge to measure the tension of Paper Machine Clothing, mostly forming fabrics. When this instrument is not in a perfect condition, it can cause serious problems in running your papermachine.

The 2 most common defects on mechanical tension gauges are:

a worn sensor bar

a leaking bellow, causing internal friction

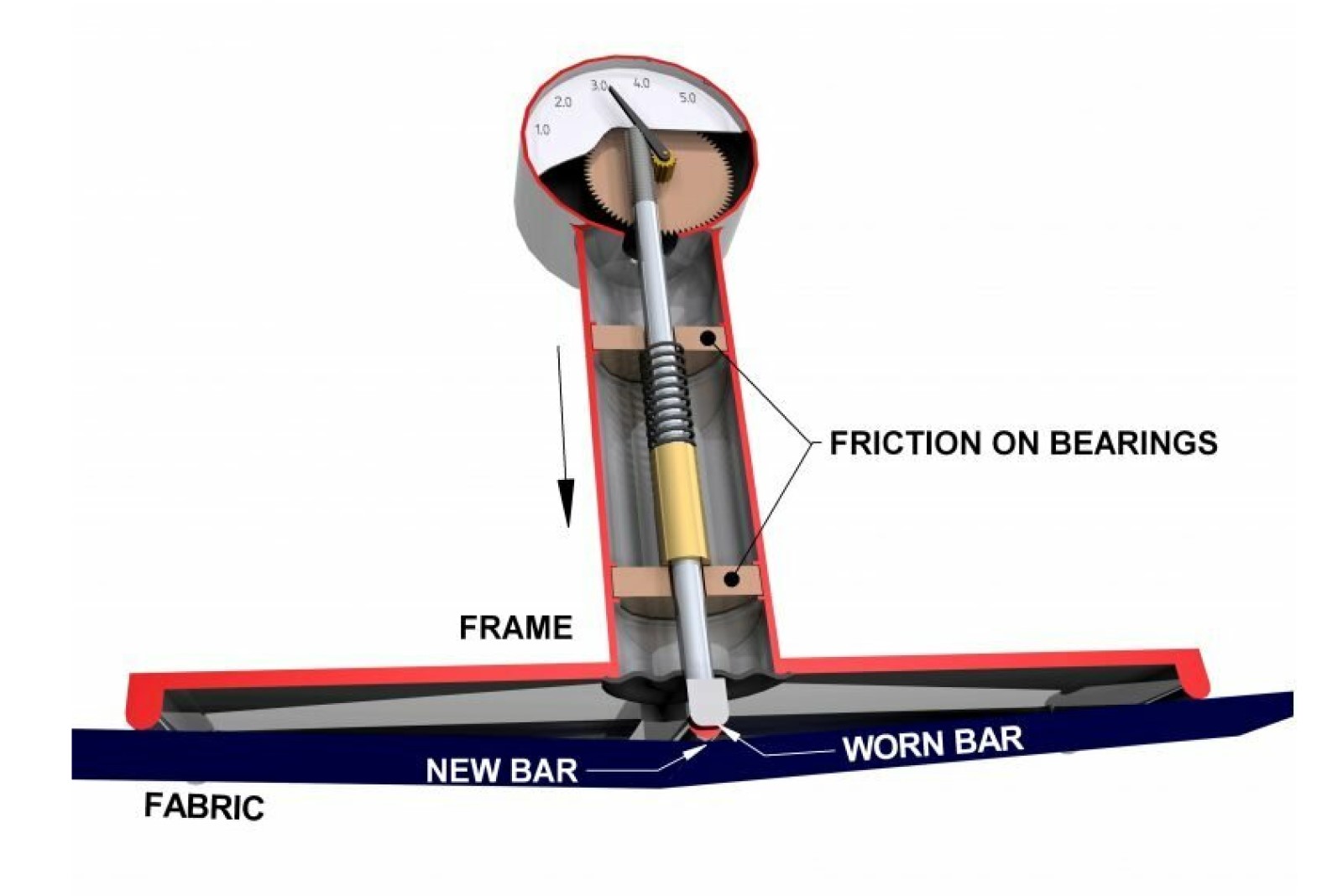

1 – worn sensor bar

If a sensor bar is worn down for several millimetres, it will push further downwards by the defined spring load, thus showing lower than the real tension value. (The higher the fabric tension, the more the bar is pushed upwards.)

2 – leaking bellow

Aging rubber material and the moving spindle will wear out the bellow, making it no longer watertight. Splash water will cause internal corrosion, giving the spindle extra mechanical resistance during measurements. The fabric will not push the sensor bar upwards as easily as it should, thus showing lower values.

Both defects have the same effect on the measurements: The gauge will show a tension value that is TOO LOW.

And you will have no idea.

“Everything looks fine to me”

In many paper mills the tension gauges are considered to be functioning so long as… the needle (the sensor bar) is still moving! Meanwhile operators are basing their adjustment decisions on values that are too low. Unknowingly. Because what happens if you adjust your fabric tension based on a measured tension value that is too low? Right, you will inadvertently increase the tension of a running fabric that may have a tension that is already too high.

High fabric tension cause serious problems:

Tearing of forming fabrics

Highly tensed running fabrics are prone to tear, or break. You want to avoid the cost for unplanned downtime and replacement of torn fabrics.

Damage to guiding rolls

High tension fabric can lead to excessive bending and dislocation of guiding rolls that keep a paper machine fabric running straight. Excessive mechanical stress can lead to metal fatigue and damage to bearings and jamming of the system. Realize that you are also putting your staff at risk because accidents are more likely to happen when moving parts jam or dislocate.

Low paper quality

The bending of rolls due to high tension will cause the running fabric to move forward in the center of the machine’s width. This changes the fabric structure, its dewatering channels and hence its dewatering properties. This inconsistent structure negatively influences the quality of the paper output. I don’t have to tell you why this is bad news.

Waviness

High tension causes waviness of a paper machine fabric. Apart from the resulting runnability problems, it will also have a negative effect on paper quality output. Consult our whitepaper Poorly Maintained Tension Gauges May Cause Severe damages for comprehensive details on the negative effects of high tension. If these negative effects are the result of poorly maintained tension gauges, they can and should be avoided by every papermaker.

Whatever it takes.

And the good news is… it doesn’t take that much.

Your periodic investments for regular service or timely replacement of this precision measuring instrument far outweigh the enormous cost that are likely to occur when you don’t.

Feel free to contact me or the other Feltest team members to help you ensure that your paper machine is running as smoothly and profitably as possible.

So remember DDPP - Daily Data Powers Production.

Toward better Paper Machine Clothing,

Marcel