- Home

- Products

- AirSpeed Sensor

- Feltest AirSpeed Sensor (for SpeedController)

Feltest AirSpeed Sensor (for SpeedController)

MEASURE PRESS FELT PERMEABILITY ON THE FLY

Permeability is key to understanding your felt’s condition. The Feltest AirSpeed Sensor helps you better plan your machine downtime, use the right amount of felt cleaning agents, and troubleshoot any performance problems.

Better monitoring for better performance

It’s good practice to monitor the press felt condition on a daily basis. Permeability is key to understanding your felt’s condition, determining how water will flow through the felt mid-nip.

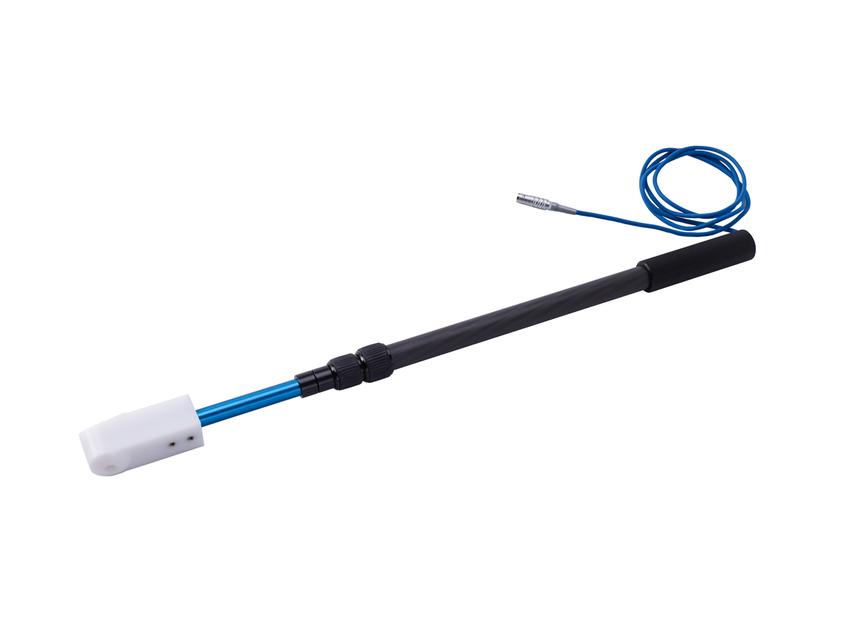

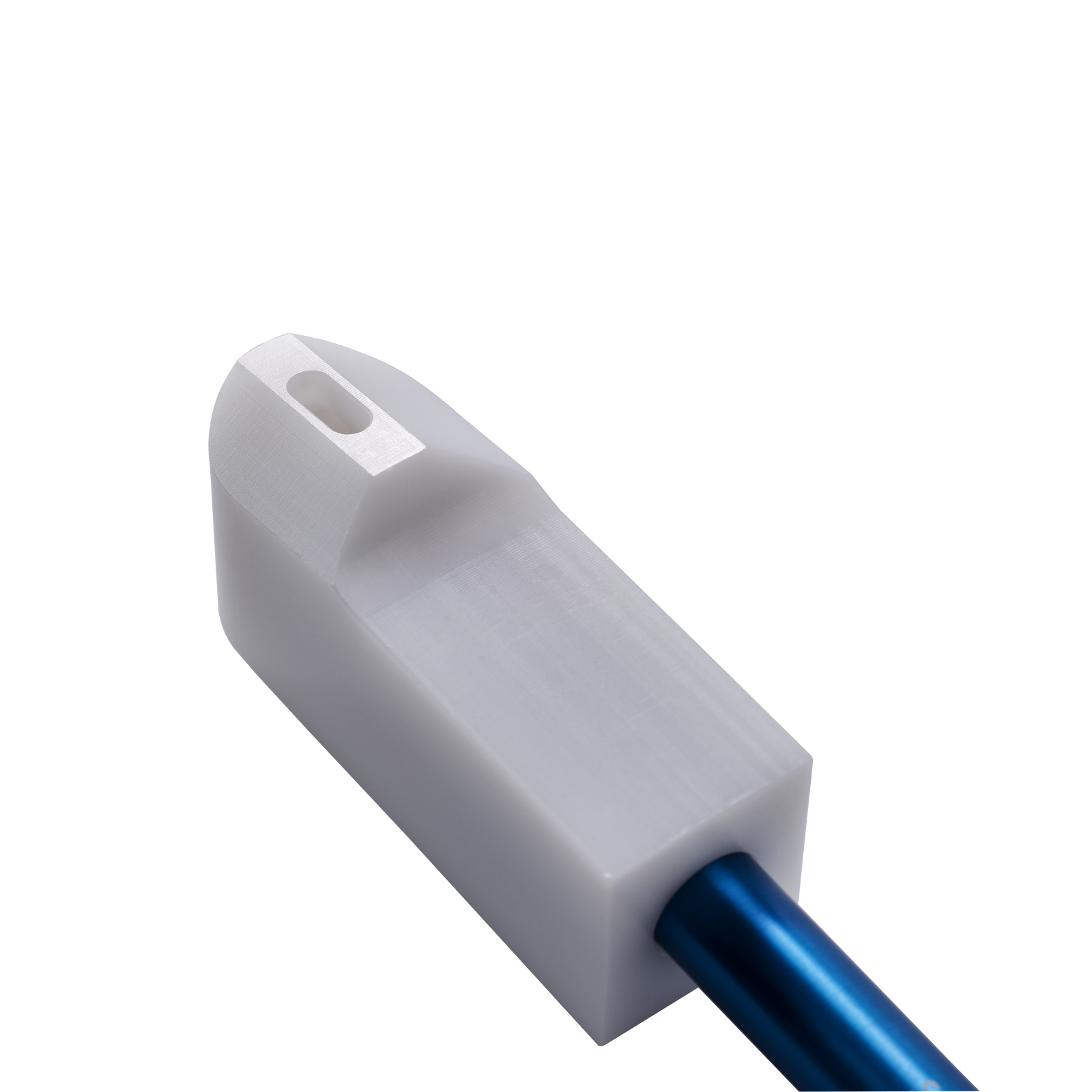

AirSpeed’s low-friction plastic measuring head contains a high precision vane that accurately measures the airspeed through the felt at both slotted and drilled uhle boxes.

If the airflow is low, poor sheet dryness or sheet crushing can be the consequences. High air flows indicate a very open felt, which can cause re-wetting or felt base marking.

Designed specifically for press felts

The AirSpeed’s low-friction plastic measuring head contains a high precision vane that accurately measures the airspeed through the felt at both slotted and drilled uhle boxes.

The telescopic carbon fiber rod makes it possible to safely measure at longer distances.

All parts of the AirSpeed Sensor are robust and built to last in the rough, hot and humid environment at the paper machine.

Fill in the form and download the brochure

It’s good practice to monitor the press felt condition on a daily basis. The Feltest AirSpeed Sensor helps you better plan your machine downtime, use the right amount of felt cleaning agents, and troubleshoot any performance problems.

FAQ's

Here are some frequently asked questions about measuring felt permeability and the AirSpeed Sensor.

This method is robust and works excellent under wet conditions.

The hot-wire is sensitive to corrosion, which is a weak point in the environment of a paper machine. That is why the AirSpeed Sensor is using a small vane (or propeller).

Yes, if the opening of the sensor head gets too dirty, the vane will rotate heavier, leading to incorrect (too low) values. To keep the test results accurate, make sure the measuring head stays clean.

On page 16 in our AirSpeed Sensor Manual, we explain how to clean the measuring head and the vane in only 3 steps.

Please note that the airspeed combined with the vacuum determines the overall press felt's condition. If you would like to know more about the applied vacuum in relation to the airspeed, look at page 10 of our SpeedController Manual.

The AirSpeed Sensor is ONLY to be used on press felts.

“The combination of a Caliper Profiler and an AirSpeed is extremely powerful when assessing press felts”

— MARCEL LENSVELT

“The combination of a Caliper Profiler and an AirSpeed is extremely powerful when assessing press felt.”

— MARCEL LENSVELT

“The combination of a Caliper Profiler and an AirSpeed is extremely powerful when assessing press felt”

— MARCEL LENSVELT

| Specifications | AirSpeed Sensor |

|---|---|

| Required Control Unit | Feltest SpeedController |

| Range | 0.5 - 20 m/s | 1.6 - 65 fps |

| To be used on | Press felts only |

| Read-out units | m/s, fps |

| Length range of telescopic carbon rod | 610 - 1010 mm | 2 - 2.2 ft |

| Length of cable | Approx. 2 m | 6.5 ft |

| Protection level | IP68 (when connected to the SpeedController) |

| Total weight | 0.4 kg | 0.9 lbs. |

Get your AirSpeed Sensor Quote

Get your quote instantly by adding it to your shopping basket and pressing the Request Quote button, or buy directly in our ONLINE STORE.

Any questions? Just reach out and our sales team will contact you shortly.