How to get reliable results from a mechanical Tensometer

Again, don't push too hard...

In two previous articles I reflected on problems related to too high or too low tension in forming fabrics.

In this article, I want to focus on the (im)proper use of the mechanical tension gauge.

The basic working principle of any mechanical tensometer is simple: a spring is pushing the sensor bar into the fabric and the actual travel of the sensor bar is converted into a tension reading on the dial.

In a slack fabric there is little resistance from the fabric against the push force of the spring, so the sensor bar travels relatively far into the fabric. On the other hand: a more taut, or tensioned, fabric is ‘pushing back’ against the spring and so reduces the travel of the sensor bar into the fabric.

You can imagine this is a delicate game between relatively small forces in the fabric and the instrument’s spring. And then: there comes the operator with 100x more muscle power in his right arm (or left arm for that matter). To get an accurate measurement with a mechanical tensometer, the trick is to let the forces in the instrument and the fabric do their work – the big, strong human should try not to interfere.

In other words: use as little force as possible when holding the instrument onto the running fabric. The more you push, the more tension you create yourself and that tension will be measured too! Result: a test value that is much higher than the actual tension in the running fabric.

Over the years I have learned that this way works best:

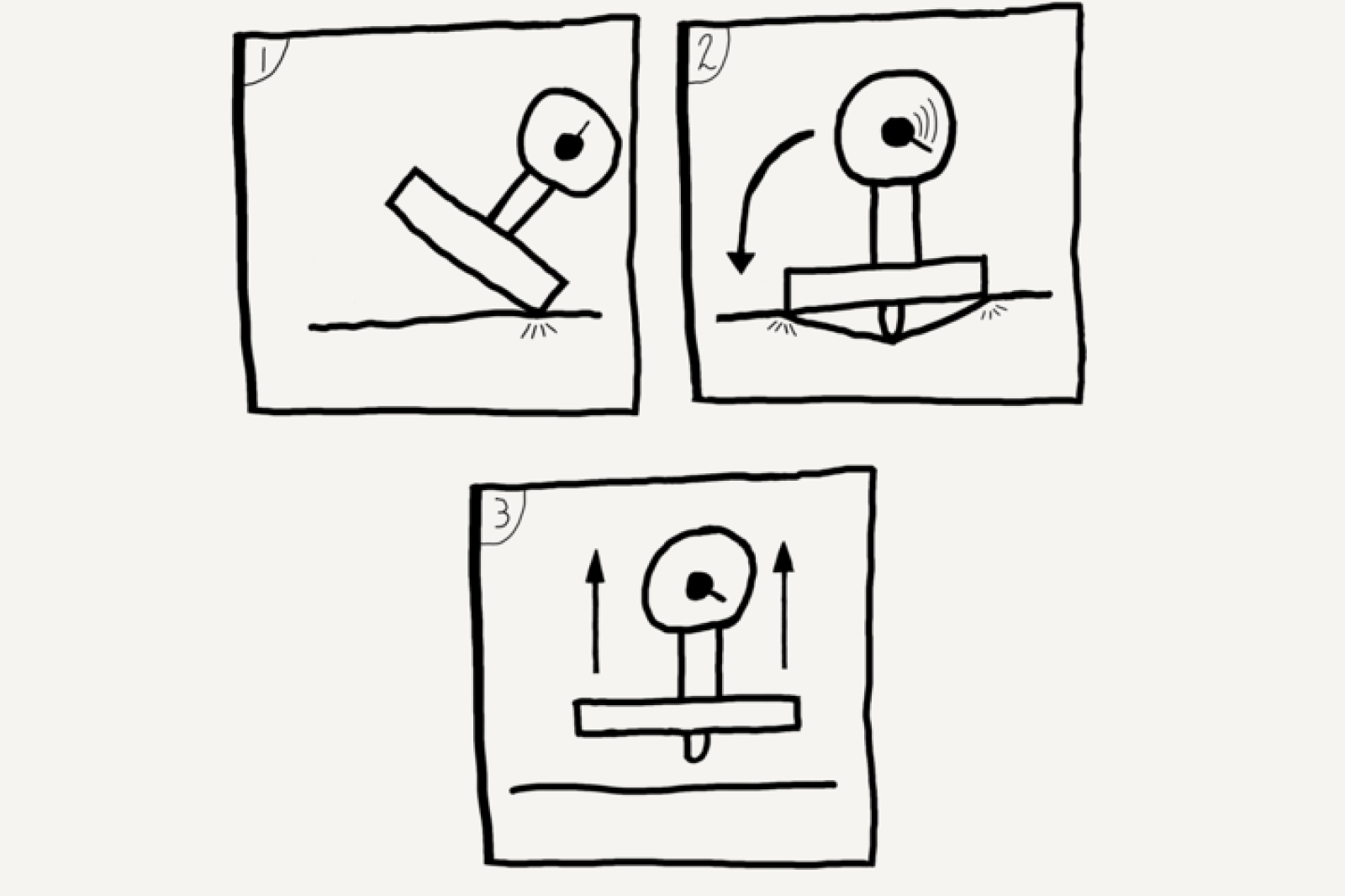

1. First let only one edge of the instrument gently touch the fabric

2. Then rotate your wrist so that the other edge touches the fabric too.

3. After both edges simultaneously touched the fabric, immediately move the instrument off the fabric.

The drag pointer of the TensioMaster will hold the highest reading for you, so you can safely read the dial outside the machine’s run.

Repeat the measurement two times and you’ll see that the instrument gives reliable and accurate results – provided the instrument is well maintained. If your tensometer is in shady condition, I would like to point out the Feltest whitepaper on poorly maintained tensometers.

If you have any questions left, or if you want to receive a quotation for a high precision Feltest TensioMaster, feel free to contact me or my Feltest team at info@feltest.com.

Get your TensioMaster quotation.

So remember DDPP - Daily Data Powers Production.

Toward better Paper Machine Clothing,

Marcel