How much life is REALLY left in your felt?

At Feltest it is our goal to provide paper mills with knowledge and easy-to-use solutions to improve the performance of their paper machine clothing.

In this article, I’d like to focus on press felts and felt permeability in particular, because it is the most important indicator for overall press felt quality. I like to view press felts as the lungs of the paper machine. Like a runner who is in perfect breathing condition to run a marathon, a press felt with perfect permeability sets the stage for optimal runnability of the whole paper machine. But as much as I like to say ‘perfect permeability’ because of the initial rhyme, perfect permeability does not exist for a press felt.

Instead of perfect permeability - I said it again - we have to talk about the best possible felt permeability because it is always a compromise between re-wetting and dewatering. Felt permeability is also highly dependent on local circumstances, such as press and roll cover design, speed, stock quality, air humidity, contamination etc.

In any event, you want to prevent the problems that occur when a felt is either too open or too dense. For example, the problem of re-wetting at the nip exit when the felt is too open or water ripping the sheet when it enters a felt that is too dense.

I’d rather talk about solutions than bore you with permeability problems. I want to relieve you of your headache of not knowing if your felt permeability is as good as it should be.

Let me start with a WARNING.

Don’t use the CFM values on a manufacturer datasheet for comparing felts or deciding on felt designs. The datasheet is good for quality assurance of the manufacturer, but it has no real use for paper makers.

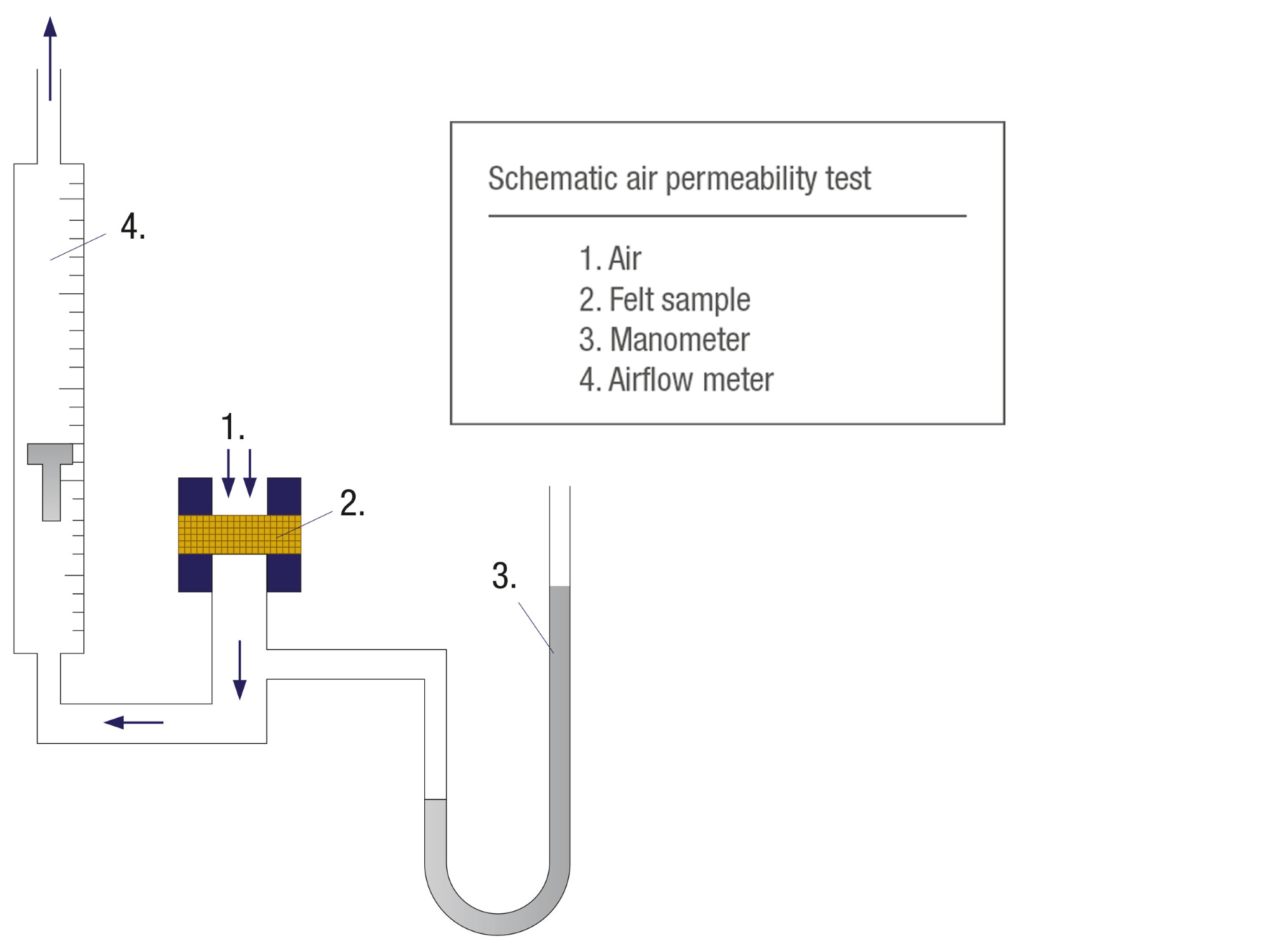

You simply don’t want to base your decisions on standards that come from a laboratory simulation. You need to measure where the action takes place – at the press felts in your running machine. I have good news for you, because measuring actual felt permeability is neither difficult nor expensive if you have the right tools.

The Feltest Airspeed/2 is a handheld tool that helps you quantify your felts operational permeability by accurately measuring the air velocity through the felt at the Uhle box while your machine is running. The Airspeed/2 is designed to function in the rough, corrosive environment of paper mills.

Being able to measure without unnecessary downtime is key to operational efficiency and cost savings. Of course the airflow is not the only parameter to judge the permeability of press felts. You need to include measurements on the applied vacuum, the caliper of the felt and the water content. If you are interested, you can read more (technical) details about the factors that determine felt permeability quality in our whitepaper on correct felt permeability.

The importance of measuring on a daily basis

While the Airspeed/2 is an ideal monitoring tool to ensure the quality of your press felts still meets your requirements, I want to point out another important thing. As a papermaker you can avoid production loss and achieve better operational results by measuring felt permeability on a regular basis.

Regardless of the tools or suppliers you choose to work with, learning from objective data for all machine conditions will accelerate your knowledge of what works best in a situation that is relevant for your paper mill. When you measure at regular intervals, for instance every day at 9 AM, you get the data you need to choose the most appropriate action before the machine itself lets you know by its poor runnability.

I don’t want to see you replace your press felts according to a pre-set schedule, only to discover that you had 8 days of life left in your felt. Neither do I want your felt to break because you failed to detect a permeability problem indicating that something was seriously wrong.

“The best decisions are made on REAL independent data.”

How much money you will save by measuring daily, will depend on the specifics of your situation. But if you look at all the different instruments, felt measuring tools have the best payback value for a paper mil. The Airspeed/2 is no exception. For instance, if you can prevent only one breakdown, you earn back your investment THREE times or more. In just 20 minutes.

Ownership versus supplier service

While papermakers still appreciate the efforts and knowledge shared by experienced service engineers, I continue to observe that the attitude towards free service measurements from paper machine clothing suppliers is shifting towards a more independent position.

Mills from groups like Domtar, PCA and UPM are already doing several standard/daily measurements themselves while calling in the suppliers service engineers for more complex analysis.

I believe what is in the best interest of a paper mill, is also in the best interest of a felt manufacturer. Think of it this way: Felt manufacturers that share our commitment to continuous improvement will only welcome independent data that gives them accurate information about the real quality and durability of their felt press under real conditions in the paper mill.

So remember DDPP - Daily Data Powers Production.

Toward better Paper Machine Clothing,

Marcel