Felt Permeability: a Simple Breakdown

A lot of papermakers come to our website to learn about felt permeability and how it affects the performance of their paper machine. In this blog series, we share a simple breakdown of what felt permeability is, and why it matters.

Felt porosity vs. permeability

The most difficult task for a felt designer is to develop felts with the best possible porosity—the felt’s ability to hold water—and the best possible permeability—how easily water (or air) flows through the felt.

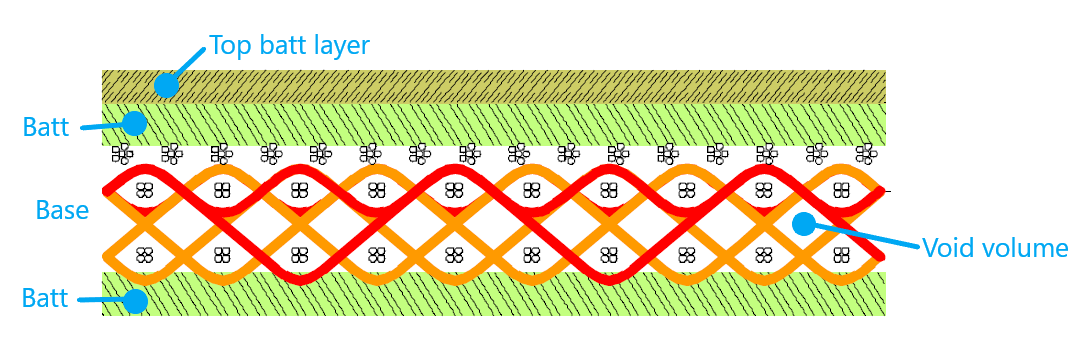

The porosity is determined by the felt’s base weave, which is a combination of warp and weft yarns, weaved together on a loom.

A single layer fabric has one layer of warp yarns, while a double layer has two. But the yarn used in base weaves varies in material, shape, and size, so a felt supplier might have 50 or more base weave designs to choose from—hence why achieving the best outcome is so complicated.

The permeability is designed and controlled by the batt; the soft cover you see on every press felt. It’s made of polyamide fibers which come in different grades of fineness, with the coarsest fibers sitting on top of the base weave, and finer fibers contacting the paper sheet.

Felt designers can experiment with the number of batt layers, and the weight per layer, which again makes the number of possible combinations endless.

Measuring what matters

Felt manufacturers will measure their felt’s air permeability as part of their quality control measures. But this measurement often ends up being of limited value for the papermaker.

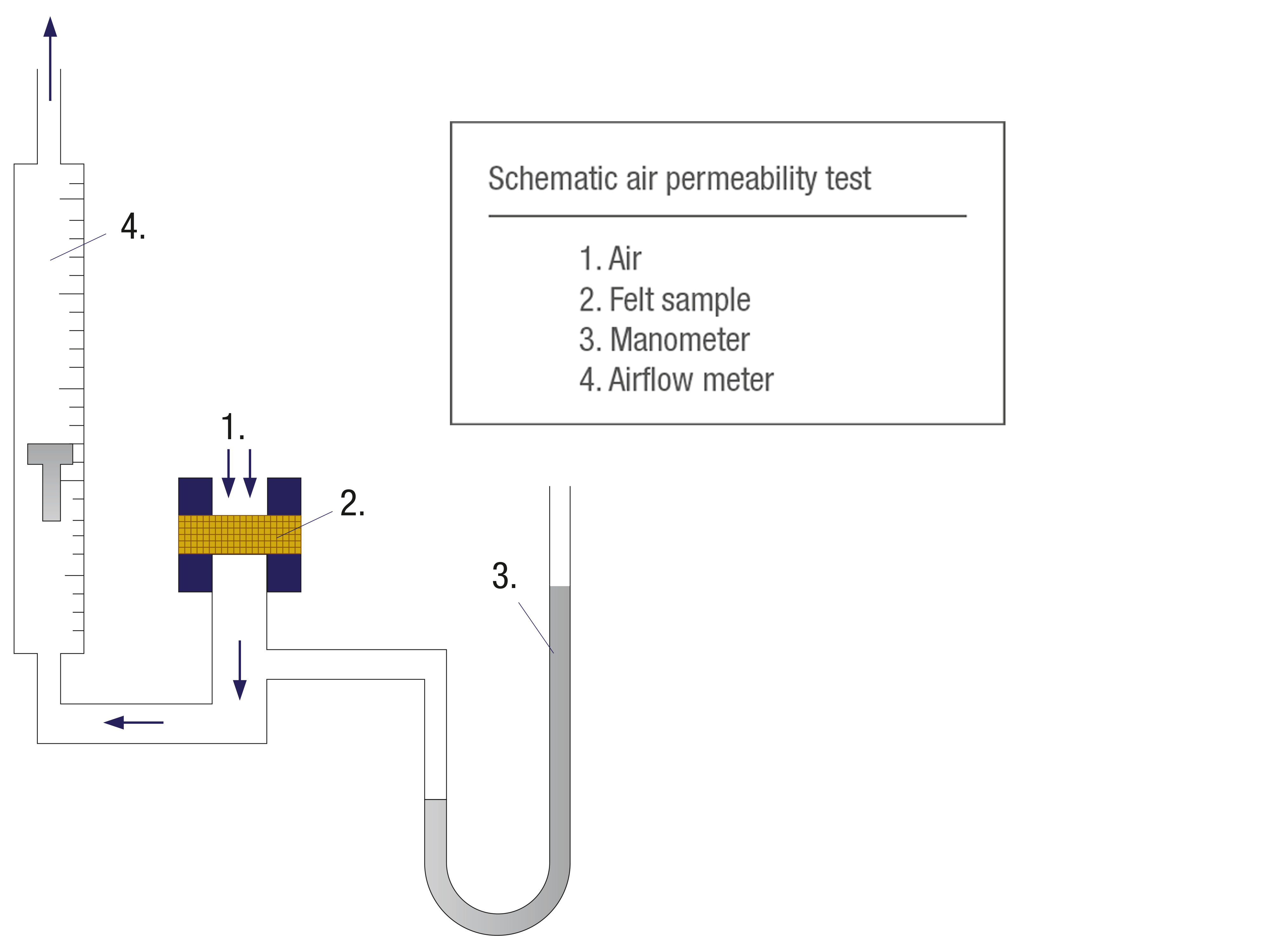

The felt manufacturer will determine air permeability by applying a very small pressure difference between the two sides of a felt sample—and then measuring in Cubic Feet per Minute (CFM) how much air flows through. The less air that passes through, the lower the CFM value.

But CFM values are of no value for papermakers

This procedure works well for plain fabrics, such as forming fabrics and dryer screens, but not so much for press felts.

With a press felt, the batt we mentioned earlier is far denser than the base fabric, so the top batt layer mostly determines the quantity of airflow. The batt also absorbs water, so the CFM value may vary with local air humidity; higher humidity causes thicker batt fibers, so the lower the air permeability becomes.

This test barely represents how felts are actually used: large amounts of water, not air, passing through a compressed felt under high pressure. Hence why CFM values are of no value for the papermaker.

So what’s the actual goal?

The goal is to find the right permeability level, but this is the most difficult task for the felt designer.

High permeability during the nip entry zone means water will easily flow from the sheet into the felt. But with high permeability at the nip exit, water will just as easily flow back into the sheet. Rewetting at its worst!

On the other hand, too low permeability is also not good. The water removal will be unsatisfactory, leading to all kinds of efficiency killers (for example, crushing, when water cannot properly flow through the felt, takes a random direction, and destroys the sheet).

In the end, there is only a limited sweet spot where the felt permeability is just right. In our next article, we explain how to achieve optimal permeability—and why it's critical for your paper machine’s runnability and output.